It is easy to dismiss virtual reality as a plaything – an immersive new media limited to storytelling and gaming – but it has so much more to offer. There are solid and practical applications that explain why so much money is being poured into the technology. This post will explore just some of these applications.

Training

When it comes to training, there is no substitute for hands-on practice. One can know all the theory behind CPR, but it is only through hours of intimate contact with a practice dummy, do trainees become competent in its execution. But the real value of physical training comes in the form of drilling – repeating an action over and over until it becomes second nature.

Consider the case of a fire in your building. You may be unconcerned because you’re confident that in the case of a hellish inferno, you will be cool, calm and collected – but can you say the same for all the others in your building? It is well understood that in emergencies, panic can spread quickly, and where there is panic, only drilled training can be relied upon for results. It is for this reason that fire-drills are carried out physically – they are designed to literally take you through the motions so that they become automatic in the case of an emergency.

However, hands-on training can be expensive and dangerous. Consider the case of an operator becoming familiar with machinery that is safety-critical in a power plant. A dummy panel could be mocked-up, but it would be expensive. The trainee could sit at the controls with a supervisor overseeing their every action, but this too is expensive and potentially dangerous. A neat substitute may be a VR ‘game’ in which the training takes place; an exact simulacrum of the controls in a world that throws endless situations at the player. The trainee could use the simulator for as long as required, and hone their skills with the machine before ever having sat down at the controls. If you think it’s far-fetched, it has already been done. NASA made use of VR to familiarise people (and potential astronauts) with the layout of the ISS. Given the ludicrous price of getting people up there, you can be sure that this kind of simulator has practical value for NASA. Check it out: https://www.oculus.com/experiences/rift/1178419975552187/

Design and Showcasing your Work

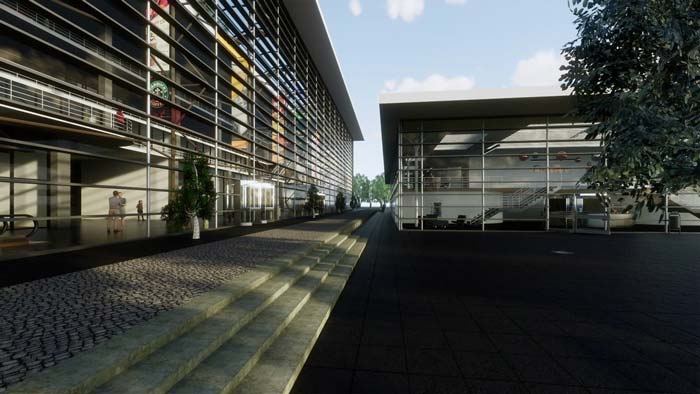

Much of the work of product designers and architects is in getting their designs just right in order to evoke the right response from the user. Capturing the feeling of standing in a cavernous marble atrium is difficult even with a good rendering, let alone a 3D modelling tool – the 2D panels of computers are simply not equipped to provide such an experience. But what if it were possible to stand in the atrium as it was being designed – a live rendering you could walk about in? This would allow the architect to get the design just right well before it is built.

For Revit, that dream has already come true in the form of the plugins Revit Live and Enscape3D. Out of the box, you’re able to don a VR headset like Oculus or Vive, and with a click of a button, be placed in the middle of your design. It is surreal to be standing in the middle of a windowed hall that you just whacked together, and use your hand to change the time of day. How the light affects the look and the feel of the room is more than just rendered in real time: it is experienced.

In the realm of the product design, VR still has a little way to go, but it is not a far cry to expect full VR support for 3D modelling tools like 3ds Max and Inventor to pop up shortly. To be able to see your product in the middle of a room, or hold it in your ‘hand’, will undoubtedly be as great an aid for product designers as it is for architects.

Augmented Reality and the Inspection of Works

It’s been joked about that Augmented Reality (AR) is just VR with better tracking and a transparent background. In the world of quality-assurance, however, these qualities are non-trivial. Presently, when a work is completed, there is the hard task of inspecting it thoroughly to make sure that the as-built reflects the model. In the area of geometry, this usually involves micrometres, measuring tapes, spirit levels, surveyors and at the higher-end drones, and laser-spectroscopy. None of these tools, however, offer quick and understandable results. The future QA officer will don an AR headset and walk around a completed work – whether it is an engine block or an entire building. The headset will overlay the 3D model over what was actually built, and highlight where there are deviations. Quickly and accurately, we’ll be able to see if what was built is up to scratch – at least geometrically.

Conclusions

We’ve really just scratched the surface in this post. There are a plethora of other potential applications for VR and AR, and it will be fascinating to see how this technology will change the way we do design, construction, manufacturing, medicine, training and many other things. Personally, I can’t wait to have a whole new way to do 3D modelling – one that lets me get the details just right.